The Importance of Metal Hardware Machining in Precision Manufacturing

When it comes to precision manufacturing, metal hardware machining plays a crucial role. From creating intricate parts to ensuring the highest standards of quality, this process is vital in various industries. In this article, we will explore the different aspects of metal hardware machining and its significance in precision manufacturing.

The Basics of Metal Hardware Machining

Metal hardware machining refers to the process of shaping metal components into the desired form using various cutting tools and techniques. This precise manufacturing method involves removing excess material from a workpiece to achieve the desired shape and size. The end result is a high-quality metal part that meets specific design requirements.

The Importance of Precision in Metal Hardware Machining

Precision is of utmost importance in metal hardware machining. The ability to accurately shape and size metal components ensures the functionality and performance of the final product. Whether it's a small component for a consumer electronic device or a critical part for an aerospace application, precision machining guarantees that every piece fits perfectly.

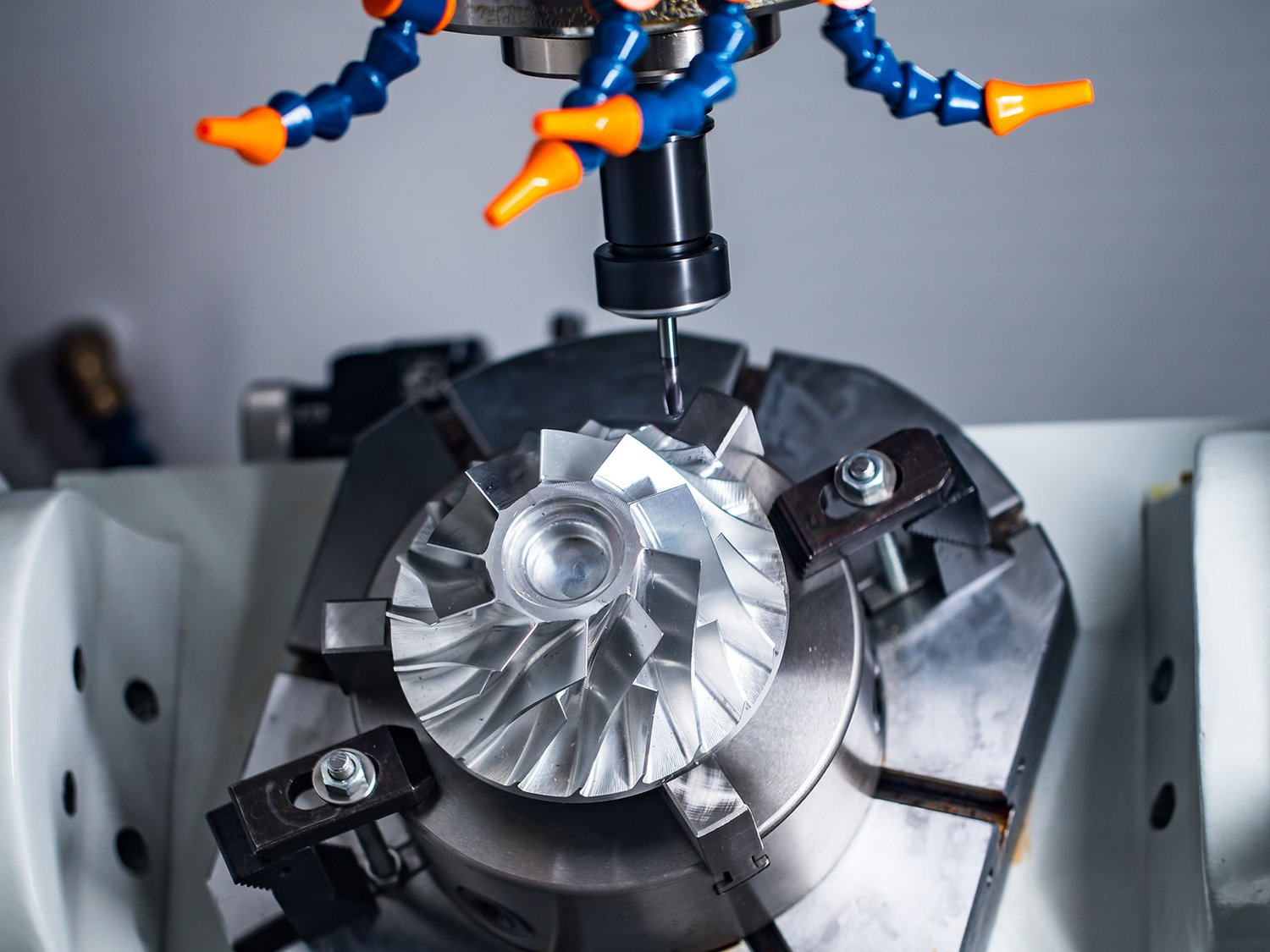

The Role of CNC Machining in Metal Hardware Manufacturing

Computer Numerical Control (CNC) machining has revolutionized metal hardware manufacturing. This automated process utilizes computer-controlled machines to precisely cut and shape metal components. The use of CNC machines enhances accuracy, speed, and repeatability, resulting in consistent and high-quality metal parts.

The Different Types of Metal Hardware Machining Processes

There are various metal hardware machining processes employed in precision manufacturing. Some of the commonly used techniques include:

1. Turning

Turning is a machining process that involves rotating the workpiece while a cutting tool removes material. This technique is suitable for creating cylindrical shapes and is commonly used in the production of shafts, pins, and valves.

2. Milling

Milling is a versatile machining process that utilizes rotary cutters to remove material from a workpiece. It is ideal for creating complex shapes, slots, and holes. Milling machines are commonly used in industries such as automotive, aerospace, and medical.

3. Drilling

Drilling is a machining process that creates holes in metal components using a rotating drill bit. This process is crucial in precision manufacturing for creating holes of varying sizes and depths. Drilling machines are widely used across industries for applications ranging from electronics to construction.

4. Grinding

Grinding is a precision machining process that uses abrasive wheels to remove material from the workpiece. It is employed to achieve tight tolerances and smooth surface finishes. Grinding is commonly used in tool and die making, as well as in the production of precision components.

5. Boring

Boring is a machining process that enlarges existing holes or creates straight, cylindrical holes in metal components. This technique is commonly used in the manufacturing of engine cylinders, hydraulic cylinders, and gun barrels.

The Advantages of Metal Hardware Machining

Metal hardware machining offers several advantages over other manufacturing processes. Some of the key benefits include:

1. Precision and Accuracy

With metal hardware machining, manufacturers can achieve high precision and accuracy, ensuring the exact dimensions and specifications are met. This is especially crucial in industries where even the slightest deviation can lead to functionality issues or safety concerns.

2. Versatility

Metal hardware machining allows for the production of a wide range of complex shapes and parts. From intricate designs to customized components, this process offers versatility that is difficult to achieve with other manufacturing methods.

3. Efficiency and Cost-Effectiveness

Modern machining technologies, such as CNC machining, have significantly improved efficiency and reduced production costs. Automation, faster turnaround times, and the ability to process multiple workpieces simultaneously contribute to the cost-effectiveness of metal hardware machining.

4. High-Quality End Products

Metal hardware machining ensures the production of high-quality end products that meet strict quality standards. The use of advanced machining techniques and tools minimizes the risk of errors and defects, resulting in reliable and durable metal components.

Conclusion

Metal hardware machining is an indispensable process in precision manufacturing. Its ability to shape metal components with precision, accuracy, and efficiency makes it essential in various industries. From CNC machining to the different types of machining processes, understanding the fundamentals of metal hardware machining is crucial for manufacturers and designers alike. By harnessing the power of this precise manufacturing method, businesses can achieve superior product quality and meet the demands of an ever-evolving market.