Introduction

CNC machining, which stands for Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls and machine tools to produce precise and complex parts. This versatile technology has revolutionized the manufacturing industry, offering numerous benefits and applications across various sectors. In this comprehensive guide, we will explore the ins and outs of CNC machining, from its basic principles to its advanced capabilities and future prospects.

1. Understanding CNC Machining

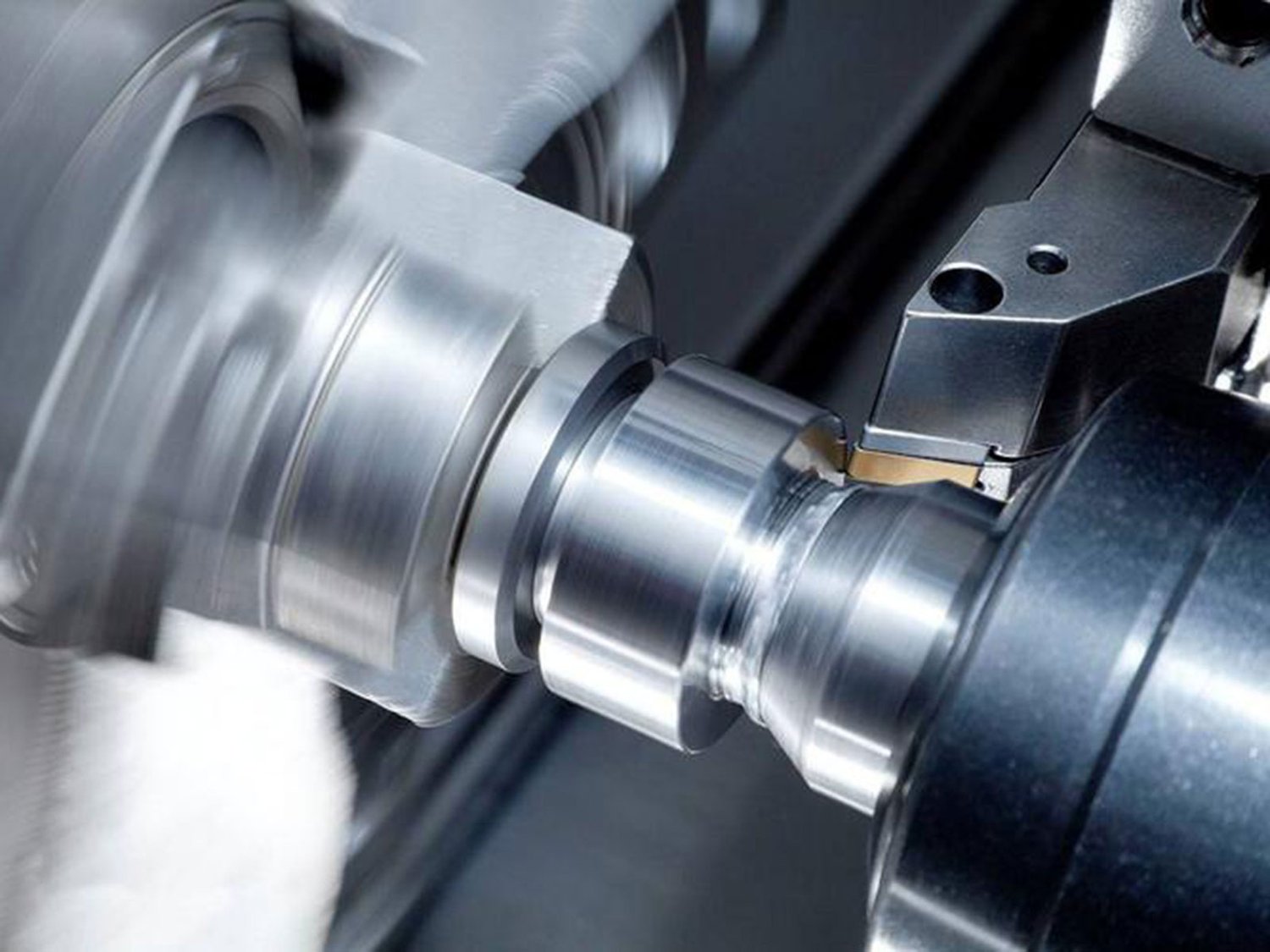

CNC machining involves the use of computer programs to control machine tools and execute pre-programmed sequences of machining operations. These operations include cutting, drilling, milling, turning, and more. The machines used in CNC machining are equipped with numerical control systems that interpret the design specifications and convert them into precise movements of the cutting tools.

2. The Advantages of CNC Machining

CNC machining offers numerous advantages over conventional manual machining techniques. One of the key benefits is its exceptional precision and accuracy. CNC machines can consistently produce parts with tolerances as low as a few microns, ensuring high-quality end products. Additionally, CNC machining allows for increased productivity and efficiency, as it eliminates the need for manual intervention and minimizes human error.

3. Applications of CNC Machining

CNC machining finds applications in a wide range of industries, including aerospace, automotive, medical, electronics, and more. It is used for manufacturing components such as engine parts, surgical instruments, electronic enclosures, prototypes, and complex 3D shapes. The versatility of CNC machining makes it an essential technology for both large-scale production and rapid prototyping.

4. Different Types of CNC Machines

CNC machining encompasses various types of machines, each designed for specific purposes. Some common types include CNC milling machines, CNC turning machines, CNC routers, CNC laser cutters, and CNC plasma cutters. Each machine type has its own set of capabilities and is suitable for different materials and machining operations.

5. Materials Suitable for CNC Machining

CNC machining can work with a wide range of materials, including metals, plastics, and composites. Metals commonly machined using CNC include aluminum, steel, brass, and titanium. Plastics such as ABS, acrylic, and nylon are also compatible with CNC machining. The material selection depends on the desired properties of the end product, such as strength, durability, heat resistance, or electrical conductivity.

6. The CNC Machining Process

The CNC machining process involves several steps, starting with the creation of a digital design using Computer-Aided Design (CAD) software. The CAD file is then converted into a format readable by the CNC machine's software, which generates the toolpaths and machining instructions. The machine operator sets up the workpiece, installs the appropriate tools, and initiates the machining process. After completion, the machined part undergoes inspection and any necessary finishing operations.

7. CNC Machining vs. 3D Printing

While CNC machining and 3D printing are both additive manufacturing technologies, they differ in terms of operation and application. CNC machining involves the removal of material from a solid block to create the final part, whereas 3D printing builds the part layer by layer using melted or cured material. CNC machining is ideal for producing high-precision, functional parts with excellent mechanical properties, while 3D printing is better suited for rapid prototyping and complex geometries.

8. Trends and Innovations in CNC Machining

CNC machining continues to evolve with advancements in technology. One notable trend is the integration of artificial intelligence (AI) and machine learning algorithms into CNC systems, enabling predictive maintenance, real-time monitoring, and optimization of machining processes. Additionally, the rise of multi-axis CNC machines allows for more complex and intricate machining operations, reducing the need for multiple setups and improving overall efficiency.

9. The Future of CNC Machining

The future of CNC machining looks promising, driven by advancements in automation, robotics, and smart manufacturing. As industries increasingly demand higher precision, faster turnaround times, and cost-effective solutions, CNC machining will play a vital role in meeting these requirements. Additionally, the integration of CNC machining with other technologies, such as additive manufacturing and Internet of Things (IoT), will open up new possibilities and further enhance the capabilities of this versatile manufacturing process.

Conclusion

CNC machining has revolutionized the manufacturing industry, offering unparalleled precision, productivity, and versatility. From its basic principles to its advanced applications and future prospects, this guide has provided a comprehensive overview of CNC machining. Whether it's producing critical components for aerospace or creating intricate medical devices, CNC machining continues to push the boundaries of what is possible in the world of manufacturing.