Anodizing

100,000 collaborative factories:Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

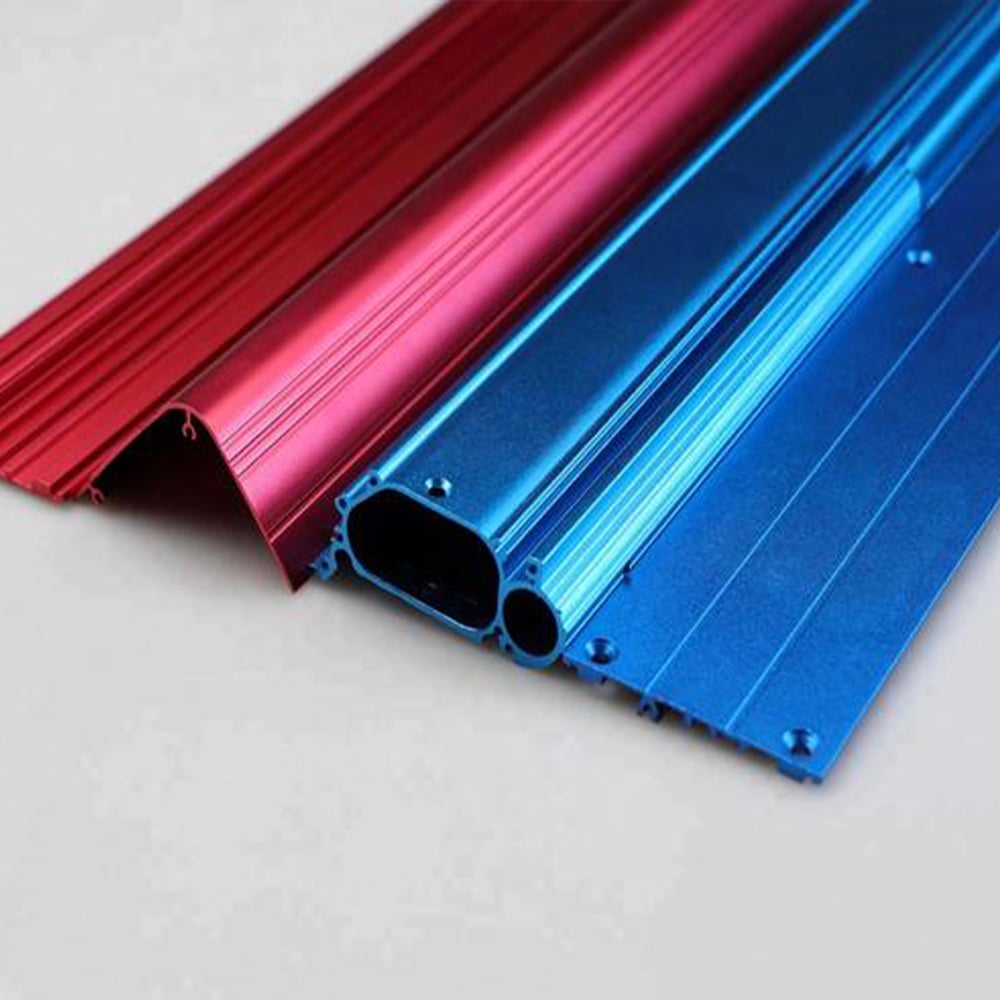

Anodizing: Enhancing the Durability and Aesthetics of Your Products

Are you looking for a way to enhance the durability and aesthetics of your products? Look no further than anodizing! Anodizing is a process that creates a protective layer on the surface of metal products, making them more resistant to corrosion, wear, and tear. In this comprehensive product description, we will explore the various aspects of anodizing and why it is a must-have for your products.

Anodizing is an electrochemical process that transforms the outer layer of metal into a durable and corrosion-resistant oxide. This process involves immersing the metal in an electrolytic solution and passing an electric current through it. The result is a thick layer of oxide that is tightly bonded to the metal surface. Anodizing can be applied to a wide range of metals, including aluminum, titanium, and magnesium, offering versatility in its applications.

One of the key advantages of anodizing is its ability to enhance the corrosion resistance of metal products. The anodized layer acts as a barrier, preventing moisture, chemicals, and other corrosive elements from reaching the metal surface. This makes anodized products ideal for outdoor applications or environments with high humidity or corrosive substances. With anodizing, you can ensure that your products will withstand the test of time and maintain their functionality and appearance.

In addition to corrosion resistance, anodizing also enhances the wear and scratch resistance of metal products. The anodized layer provides a hard and durable surface that is more resistant to abrasion and scratches compared to untreated metal surfaces. This makes anodized products suitable for high-traffic areas or products that undergo frequent handling. With anodizing, you can rest assured that your products will maintain their pristine appearance, even after years of use.

Anodizing offers a wide range of color options, allowing you to customize the appearance of your products. The anodized layer can be dyed in various colors, including vibrant shades and metallic finishes. This versatility in color options allows you to create products that align with your brand identity or cater to specific customer preferences. Whether you prefer a sleek and modern look or a bold and vibrant aesthetic, anodizing can help you achieve the desired visual impact.

Anodizing is an environmentally friendly process that produces minimal waste and consumes less energy compared to other surface treatment methods. The electrolytic solution used in anodizing is typically water-based and does not contain hazardous chemicals. Additionally, the anodized layer is non-toxic and does not release harmful substances into the environment. By choosing anodizing, you not only protect your products but also contribute to sustainable manufacturing practices.

Anodizing creates a surface that improves the adhesion of coatings, such as paints or adhesives, to the metal substrate. The porous nature of the anodized layer allows coatings to penetrate and bond more effectively, resulting in a stronger and more durable finish. This makes anodized products an excellent choice for applications where additional coatings or finishes are desired, such as automotive parts or architectural components.

Anodizing imparts electrical insulation properties to metal products, making them suitable for electrical and electronic applications. The anodized layer acts as an insulator, preventing electrical current from passing through the metal surface. This is particularly useful in industries where electrical conductivity can pose a risk, such as aerospace or electronics. With anodizing, you can ensure the safety and reliability of your electrical components.

Anodized products exhibit excellent heat resistance and thermal stability, making them suitable for high-temperature environments. The anodized layer can withstand elevated temperatures without significant degradation or loss of protective properties. This makes anodized products ideal for applications that involve exposure to heat, such as engine components, cookware, or industrial machinery.

Thanks to its smooth and non-porous surface, anodized products are easy to clean and maintain. The anodized layer resists staining and is less prone to accumulating dirt, grime, or fingerprints compared to untreated metal surfaces. Cleaning anodized products simply requires mild soap and water or non-abrasive cleaners. With minimal effort, you can keep your anodized products looking brand new and ensure their longevity.

Despite its numerous benefits, anodizing is a cost-effective solution for enhancing the durability and aesthetics of your products. The process is relatively quick and efficient, resulting in lower production costs compared to alternative surface treatment methods. Additionally, anodized products have a longer lifespan and require less maintenance, reducing overall expenses in the long run. With anodizing, you can achieve exceptional results without breaking the bank.

Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.