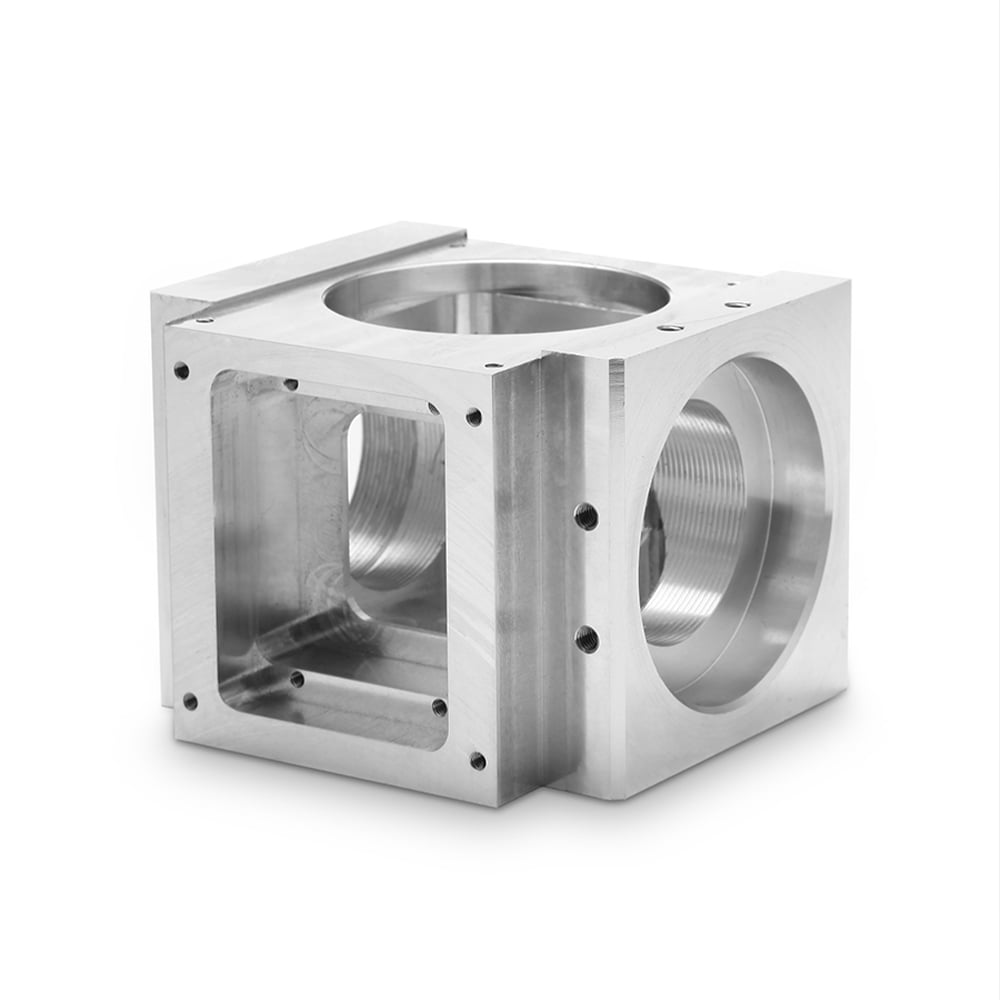

Aluminum shell cavity machining

100,000 collaborative factories:Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

High Precision Aluminum Shell Cavity Machining for Superior Performance

Aluminum shell cavity machining is a cutting-edge technology that revolutionizes the manufacturing industry. With its high precision and superior performance, this process allows for the creation of intricate aluminum shell cavities with utmost accuracy. Whether you are in the aerospace, automotive, or electronics industry, this machining technique offers unparalleled benefits and endless possibilities.

Unmatched Precision and Accuracy

When it comes to precision engineering, aluminum shell cavity machining is at the forefront. This process utilizes advanced machinery and cutting-edge software to achieve unparalleled accuracy. Each cavity is meticulously crafted, ensuring a perfect fit and optimal functionality. With this level of precision, you can expect consistent and reliable results, meeting the most demanding specifications and requirements.

Exceptional Strength and Durability

Aluminum shell cavity machining produces cavities that are not only precise but also incredibly strong and durable. The use of high-quality aluminum alloys ensures that the machined cavities can withstand extreme conditions, including high temperatures, corrosive environments, and heavy loads. This durability translates into longer product lifespan, reduced maintenance costs, and enhanced overall performance.

Enhanced Heat Dissipation

One of the key advantages of aluminum shell cavity machining is its ability to provide excellent heat dissipation. The intricate design of the cavities allows for efficient cooling, making it ideal for applications that generate significant heat. Whether it is a computer processor, power electronics, or LED lighting, the machined aluminum shell cavities dissipate heat effectively, ensuring optimal performance and preventing overheating.

Lightweight and Cost-Effective

Aluminum shell cavity machining offers a lightweight alternative to traditional manufacturing methods. The use of lightweight aluminum alloys reduces the overall weight of the product, making it perfect for industries where weight is a critical factor, such as aerospace. Moreover, the cost-effectiveness of aluminum as a material makes this machining technique an economical choice, without compromising on quality or performance.

Seamless Integration and Customization

With aluminum shell cavity machining, seamless integration of various components is made possible. The cavities can be designed to accommodate intricate wiring, connectors, or other necessary elements, ensuring a neat and organized product. Additionally, the machining process allows for customization, enabling the creation of unique designs tailored to specific requirements and preferences.

Improved Electromagnetic Shielding

Aluminum shell cavity machining is highly effective in providing electromagnetic shielding. The aluminum material used in the cavities acts as a barrier, preventing electromagnetic interference from affecting the sensitive components inside. This feature is particularly important in industries such as telecommunications, where electromagnetic compatibility is crucial for optimal performance.

Superior Surface Finish

Thanks to advanced machining techniques, aluminum shell cavity machining produces cavities with a superior surface finish. The smooth and flawless surfaces not only enhance the aesthetic appeal of the product but also contribute to its performance. The reduced friction and improved airflow achieved through the precise machining process result in optimized functionality and efficiency.

Efficient Production and Short Lead Times

Aluminum shell cavity machining offers efficient production processes and shorter lead times compared to traditional manufacturing methods. The use of advanced machinery and automation streamlines the production process, allowing for faster turnaround times without compromising on quality. This makes it an ideal choice for industries that require rapid prototyping or quick production cycles.

Eco-Friendly and Sustainable

As the world becomes more environmentally conscious, aluminum shell cavity machining stands out as an eco-friendly and sustainable solution. Aluminum is a highly recyclable material, reducing waste and minimizing the carbon footprint. By choosing this machining technique, you are not only investing in high-quality products but also contributing to a greener and more sustainable future.

Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.