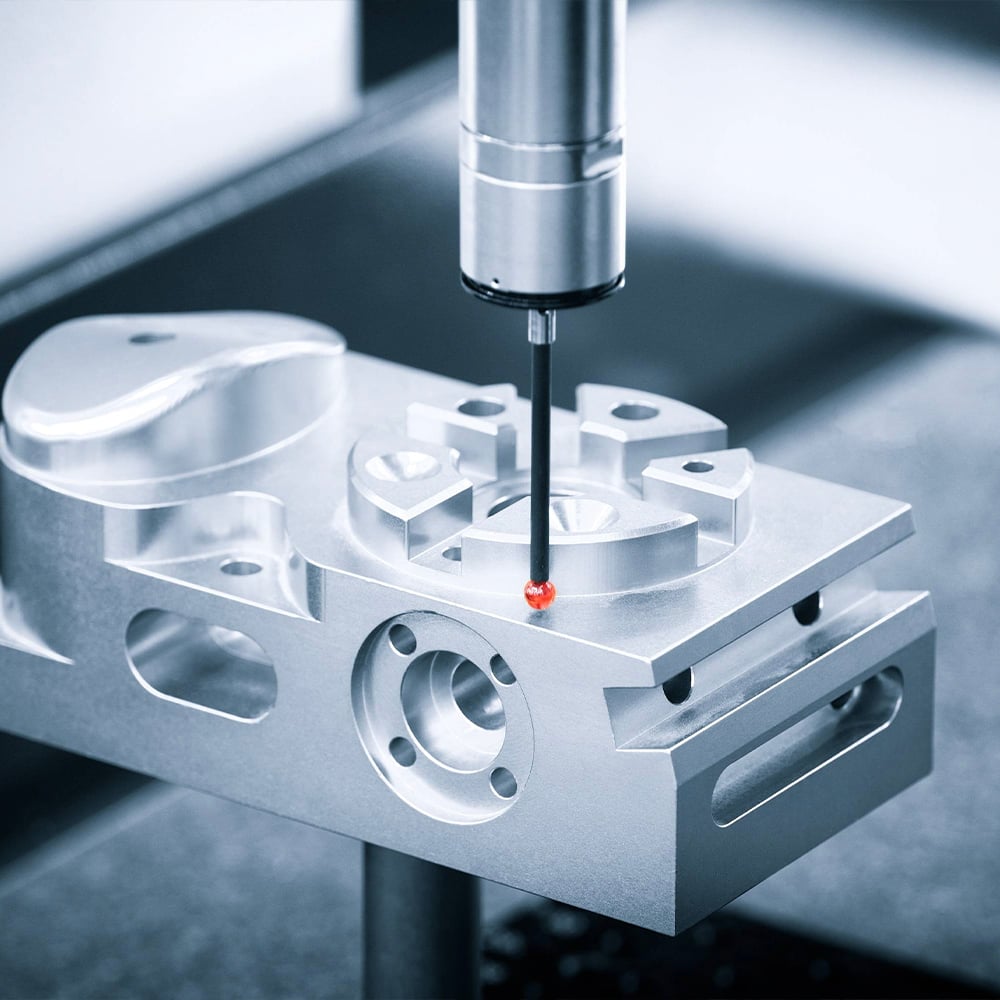

CNC machining

100,000 collaborative factories:Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

Our CNC machining service has the following advantages:

1. High precision: We use advanced CNC processing equipment and technology to achieve high-precision processing, ensuring that the size and quality of our products meet customer requirements.

2. Rapid delivery: We have an experienced work team and efficient production process, which can quickly respond to customer needs and deliver products on time.

3. Diversified processing: Our CNC processing services cover various materials and processing methods, including milling, turning, drilling and other processing techniques for aluminum alloy, stainless steel, plastic and other materials, which can meet the different processing needs of customers.

4. Cost effectiveness: By optimizing processing processes and improving production efficiency, we can reduce processing costs and provide customers with more competitive prices.

5. Customer Customization: We can customize and process according to the specific requirements of customers, including product design, material selection, processing technology, etc., to ensure that the final product can fully meet the needs of customers.

In short, our CNC machining services have advantages such as high precision, fast delivery, diversified processing, cost-effectiveness, and customer customization, which can provide customers with high-quality machining products and satisfactory services.

Experience Precision and Efficiency with CNC Machining

Are you in need of a manufacturing process that combines accuracy, speed, and versatility? Look no further than CNC machining. With its advanced technology and automated capabilities, CNC machining has revolutionized the manufacturing industry. In this product description, we will explore the various aspects of CNC machining, from its capabilities to its benefits and applications.

Unleash the Power of Computer Numerical Control

CNC machining, short for Computer Numerical Control machining, is a manufacturing technique that utilizes computerized controls to operate machinery. It involves the use of pre-programmed software that guides the machine to produce precise and complex parts with ease. By eliminating the need for manual intervention, CNC machining offers unmatched accuracy and consistency in every production run.

Precision at Your Fingertips

One of the key advantages of CNC machining is its exceptional precision. The computer-guided machines can achieve extremely tight tolerances, ensuring that each part meets the specified requirements. Whether you're working on intricate components for the aerospace industry or producing small parts for medical devices, CNC machining allows you to maintain consistent quality and dimensional accuracy.

Efficiency Redefined

With CNC machining, efficiency is taken to a whole new level. The automated process eliminates the need for manual adjustments and constant monitoring, freeing up valuable time for operators. Additionally, CNC machines can work continuously, 24/7, leading to faster production cycles and shorter lead times. This increased efficiency translates into cost savings and improved productivity for your business.

Endless Possibilities with Versatile Machining

CNC machining is incredibly versatile, capable of fabricating parts from various materials such as metals, plastics, and composites. Whether you require milling, turning, drilling, or grinding, CNC machines can handle an extensive range of operations. The flexibility of CNC machining allows for easy customization and adaptation to different design requirements, making it an ideal choice for prototyping or mass production.

Enhance Productivity with Automation

Automation is a key feature of CNC machining, and it brings numerous benefits to the manufacturing process. By automating repetitive tasks, CNC machines reduce the chances of errors and ensure consistent production quality. The ability to store and replicate programs also enables easy replication of parts, eliminating the need for manual programming each time. With CNC machining, you can streamline your production process and maximize productivity.

Unmatched Speed for Time-Critical Projects

When it comes to time-critical projects, CNC machining shines. Its high-speed operations allow for rapid production of parts without compromising on quality. Whether you have urgent deadlines to meet or need to quickly iterate designs, CNC machining can deliver the required components in a fraction of the time compared to traditional manufacturing methods.

Exceptional Surface Finishes

CNC machining not only excels in precision and efficiency but also delivers exceptional surface finishes. The machines can achieve smooth, mirror-like surfaces, eliminating the need for additional post-processing steps. Whether you require parts with a polished sheen or a textured finish, CNC machining can deliver the desired aesthetic appeal, enhancing the overall quality of your products.

Cost-Effective Production Solutions

Investing in CNC machining offers long-term cost savings for your business. With its high levels of automation and efficiency, CNC machining minimizes material waste and reduces the need for manual labor. The precise control over the manufacturing process also leads to fewer defects and rejections, saving you both time and money. By choosing CNC machining, you can optimize your production costs and improve your bottom line.

Applications Across Industries

CNC machining finds applications across a wide range of industries, from automotive and aerospace to electronics and healthcare. Whether it's creating intricate engine components or manufacturing complex circuit boards, CNC machining provides the precision and reliability needed for critical applications. Its adaptability and versatility make it a go-to choice for any industry that values quality, efficiency, and innovation.

Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.