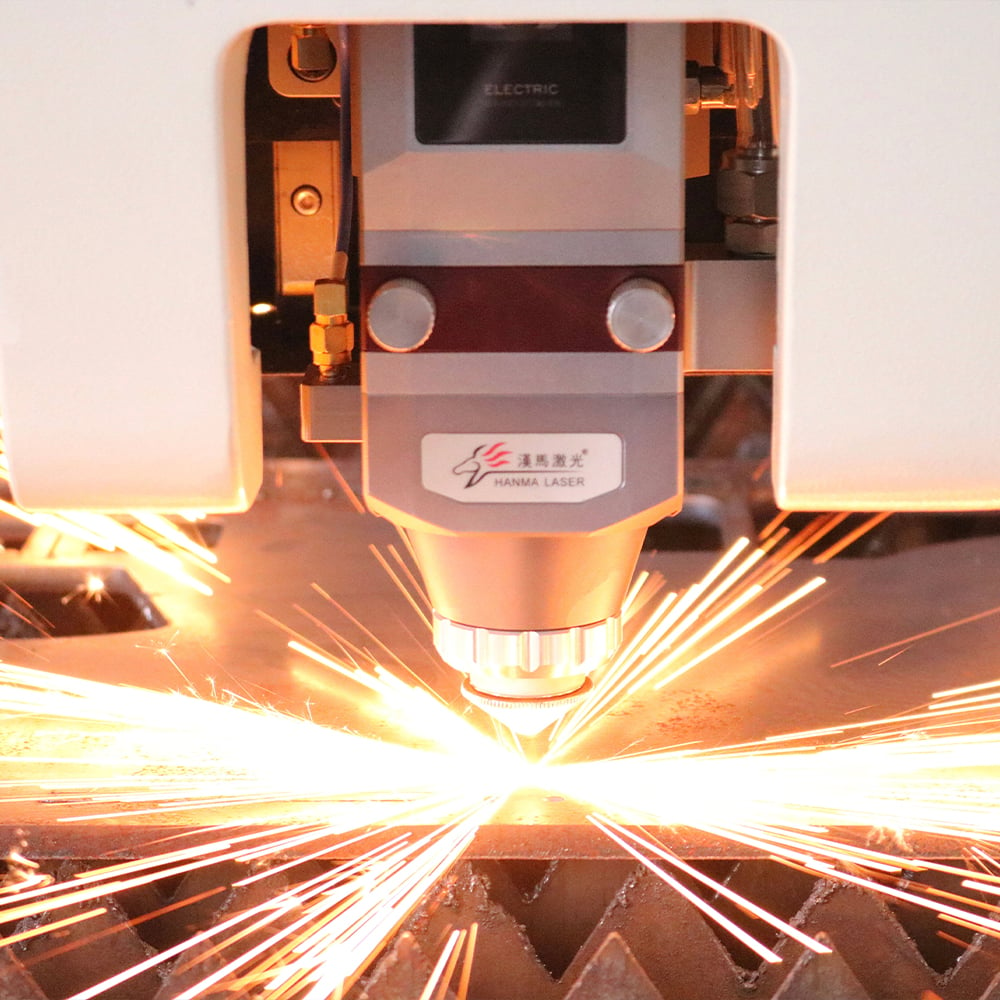

Laser cutting

100,000 collaborative factories:Whether you need assistance with prototyping, production, or sourcing, our platform offers a comprehensive solution to meet all your manufacturing needs.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

Laser Cutting: The Ultimate Solution for Precision and Efficiency

Are you in need of a cutting-edge technology that can deliver precise and efficient results? Look no further than laser cutting. This innovative process utilizes a high-powered laser beam to cut through various materials with unparalleled accuracy. Whether you require intricate designs on metal, plastic, wood, or even fabric, laser cutting is the ideal solution for a wide range of applications. Read on to discover the numerous advantages and possibilities that laser cutting brings to the table.

Unmatched Precision for Intricate Designs

Laser cutting is renowned for its ability to achieve exceptional precision, making it a go-to choice for industries that demand intricate designs. With laser cutting, you can effortlessly create intricate patterns, shapes, and cutouts with micron-level accuracy. Whether you're working on architectural models, jewelry, or signage, laser cutting ensures that every detail is captured flawlessly, resulting in a finished product that exceeds expectations.

Versatility Across a Wide Range of Materials

One of the key advantages of laser cutting is its versatility when it comes to materials. Whether you're dealing with delicate fabrics, dense metals, or brittle plastics, laser cutting can handle it all. This technology is capable of cutting through materials such as stainless steel, acrylic, leather, wood, and even glass, opening up endless possibilities for creative expression and functional applications.

Efficient and Time-Saving Process

Time is of the essence in today's fast-paced world, and laser cutting is designed to deliver results with efficiency and speed. Unlike traditional cutting methods, laser cutting eliminates the need for manual adjustments, multiple passes, and time-consuming setups. With laser cutting, you can significantly reduce production time, allowing you to meet tight deadlines without compromising on quality.

Clean and Precise Cuts without Material Distortion

When it comes to achieving clean and precise cuts, laser cutting surpasses other methods by producing minimal heat-affected zones and negligible material distortion. The focused laser beam ensures that the surrounding material remains unaffected, resulting in clean edges and minimal post-processing requirements. This means less time spent on sanding, finishing, or smoothing out rough edges, ultimately saving you time and resources.

Enhanced Safety Features for Peace of Mind

Laser cutting systems incorporate advanced safety features to ensure a secure working environment. From enclosed cutting areas to protective barriers and sensors, these safety measures minimize the risk of accidents and injuries. Additionally, laser cutting eliminates the need for physical contact with the cutting tool, reducing the chances of operator-related mishaps. With laser cutting, you can focus on your work with peace of mind.

Seamless Integration with Computer-Aided Design (CAD) Software

Laser cutting seamlessly integrates with computer-aided design (CAD) software, allowing for precise and complex designs to be translated into reality. By simply importing your design file into the laser cutting system, you can achieve accurate and consistent results every time. This integration eliminates the need for manual measurements and calculations, ensuring that your designs are faithfully replicated without any errors.

Scalability for Small and Large-Scale Productions

Whether you're a small business looking to create prototypes or a large-scale manufacturer producing thousands of products, laser cutting offers scalability to meet your needs. With its efficient and automated process, laser cutting can handle both small and large-scale productions with ease. This scalability allows you to increase your production capacity without compromising on quality or accuracy.

Minimal Material Waste for Cost-Effective Production

Wasted materials can significantly impact production costs, but laser cutting minimizes material waste through its precise cutting capabilities. By optimizing the cutting path and minimizing the gap between parts, laser cutting ensures that material usage is maximized, reducing waste and saving you money in the long run. This cost-effective production method allows you to achieve high-quality results while minimizing your environmental footprint.

Endless Possibilities for Creative and Functional Applications

From intricate jewelry designs to architectural models, laser cutting opens up a world of possibilities for both creative and functional applications. Whether you're looking to create custom signage, personalized gifts, or intricate decorations, laser cutting allows you to push the boundaries of design and craftsmanship. With its precision, versatility, and efficiency, laser cutting empowers you to turn your ideas into reality.

Certificates

With a strong foothold in the Machinery manufacturing industry, we proudly showcase an array of industry certificates that validate our commitment to excellence. These certificates, earned over the years, stand as a testament to our unwavering dedication to producing highly competitive products. By adhering to stringent quality standards and employing cutting-edge technology, we consistently deliver superior machinery that exceeds customer expectations. Our advantage lies in our ability to seamlessly integrate innovation with reliability, ensuring our products are at the forefront of the industry. We prioritize customer satisfaction by offering tailored solutions, exceptional after-sales service, and a responsive support team. Our competitive pricing, coupled with our unwavering commitment to delivering on time, further distinguishes us from the competition. Trust in our expertise, bolstered by our industry certificates, and experience the unparalleled advantages we bring to the Machinery manufacturing industry.